8 Simple Techniques For Hiring Harnesses Australia

Table of ContentsThe Best Strategy To Use For Hiring Harnesses AustraliaThings about Hiring Harnesses AustraliaOur Hiring Harnesses Australia DiariesThe 2-Minute Rule for Hiring Harnesses Australia

, a weave of extruded string, or a combination thereof.

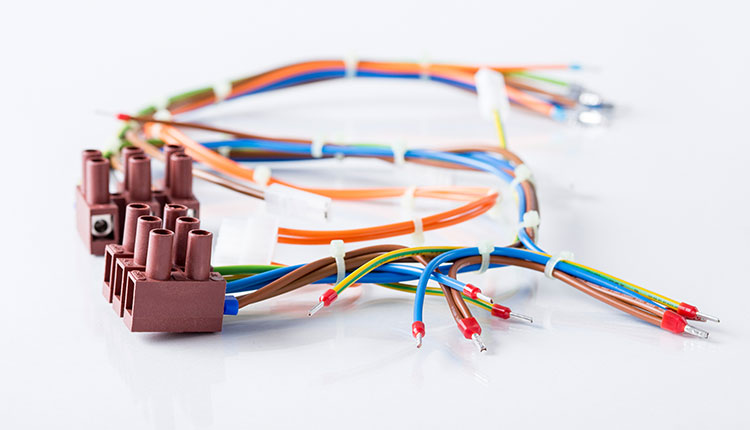

Cord harnesses are generally developed according to geometric and also electrical demands. The cables are initial cut to the preferred length, normally using an unique wire-cutting device.

Hereafter, completions of the wires are removed to subject the metal (or core) of the cables, which are fitted with any type of needed terminals or port real estates. The cords are set up as well as clamped together on an unique workbench, or onto a pin board (assembly board), according to the design specification, to develop the cord harness.

Manual manufacturing continues to be more inexpensive than automation, particularly with small batch sizes. Pre-production can be automated partly. This impacts: reducing specific cables (reducing maker), cord removing (automated cord removing makers), kinking terminals onto one or both sides of the cord, partial plugging of cables prefitted with terminals right into adapter housings (component), soldering of cable ends (solder device), turning cords.

Rumored Buzz on Hiring Harnesses Australia

When a wire harness has been generated, it is frequently based on various examinations to ensure its high quality as well as capability. A test board can be made use of to gauge the harness' electrical capacities. This is achieved with the input of data regarding a circuit which one or even more cord harnesses will belong to being programmed right into the examination board.

Draw test certification of kinky end. One more popular examination technique for a wire harness is a 'pull examination', in which the harness is attached to a machine that pulls the harness at a continuous rate. This examination then gauges the cable harness' stamina and also electrical conductivity when drawn versus a minimal basic to ensure that cable television harnesses are continually effective and also secure.

The IPC/WHMA-A -620 publication has standards for a variety of elements within a cable harness, including but not limited to electrostatic discharge security, channel, installment as well as repair services, kinking, pull-test requirements, and other operations that are essential to the manufacturing as well as feature of cable harnesses (Hiring Harnesses Australia). The standards mandated by the IPC differ based on an item's classification under one of three specified item courses.

Class 2: dedicated solution electronic items, where regular as well as extended efficiency is needed, but uninterrupted solution is not important. Class 3: see here now high efficiency electronic items, for products that need continued and regular performance and where durations of inoperativeness can not be endured.

The Hiring Harnesses Australia PDFs

A cable is a single conductor comprised of a single or multiple hairs of conductive material, normally Copper or Aluminium, which is safeguarded by a non-conductive sheath normally made from thermoplastic. A cable is a collection of cords, usually with different coloured sheaths for simple recognition, that are bound with each other inside an exterior cover.

The electrical wiring in an automobile is a system of colour-coded cords called the loom. Where several wires run alongside they are bound along with protecting tape or plastic sleeving. A number of modern-day cars and trucks have different slim wires embedded in flat plastic strips. These strips are really compact, and are used mostly for accessories and relay controls that require little power.

Where they run with an opening, the sharp edges are lined with a rubber grommet. Often the loom is split right into areas signed up with by multi-pin plugs and also sockets, to make sure that it can be removed and reconditioned area by section. Joins in individual cords are typically made with crimp connectors. The colour on the sleeve of a connector denotes the size of cable it will take.

There are multiple sleeves or various other special connectors where a wire branches off. Cords are generally attached to elements by plastic-covered terminals which push on to a blade on the device called a spade terminal. Almost all kinds of terminals ought to be fitted to the wire with kinking pliers.

8 Easy Facts About Hiring Harnesses Australia Described

For extra safety and security, you can add solder to the cord. Use a 25-65 watt iron for a lot of job, as well as a 150-250 watt one visit site for big wires, or an 8 oz (225 g) gas-heated iron. Detach both terminals of the battery prior to doing any type of work with electrical wiring apart from testing. Whenever you function on the auto, watch for any type of component of the loom coming loose from its clips, for there is a threat of it obtaining trapped or shed.

The sharp edge of the hole will quickly chafe through wire insulation and cause a short circuit. Whenever you draw a connection apart, look for rust link which may cause poor get in touch with.

As well as, since we are "personalized wiring harness" people, we'll also share some understandings into the job we do to assist our clients get the results they are trying to find. It is very important to keep in mind that the term "electrical wiring harness" is commonly utilized mutually with various other terms like circuitry loom, cable television harness and circuitry assembly.

A cord is a single strand of product, such as aluminium or copper, which performs electricity. A cord on the various other hand is composed of 2 or more insulated wires that run with each other inside a sheath.

Comments on “Not known Facts About Hiring Harnesses Australia”